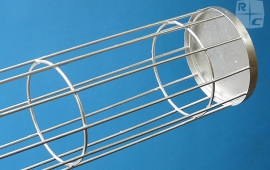

The Bag cage are used as a support of filter bag to allow air flow interior to it without collapsing the cylindrical surface form the exterior of bag and to exit through our in house unique manufacturing technology of prestressing force, to ensure the light weight and high strength spot welding of the product. The cages are made of 4 mm wire, unique horizontal ring distribution staring form both open end and 2nd ring at 70 mm gap resulting features are straight and rigid. The spot weld gives the flexibility to cage in twisting form both end which ensure.

Each cage made in RUEDO ENGINEERING can fit to the requirements of being light, handy, smooth and straight. Cage resembles the rib of bag. It should be light, handy, easy to install, maintain. And it is smooth and straight, to prevent the bag from damage. The big differences between our cages and the normal available cage are life of the filter bag due to sharp welding ends, bends in every wire, impossible to remove the cage from bag during maintenance, We ensure the problem will not be in our cages means it will enhance bag life and easy maintenance. We also make unique split cages for low head room clearance in the dust collector top.

Spot welding ensure no sharp end on the cage surface which ensure no friction with filter fabric clean side. Our special Zig and Enclosure ensure you no bending of cage, and it will be very straight and flexible to twist.

Pulse Valves

Pulse Valves Pleated Cartridge

Pleated Cartridge Filter Fabric

Filter Fabric Filter Bags

Filter Bags Din Type Cartridge

Din Type Cartridge Accessories

Accessories Dust Collector

Dust Collector Bag Cages

Bag Cages