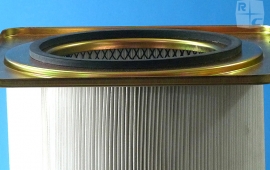

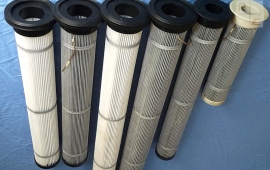

Pulsejet type pleated elements are the new generation filter bag to replace the conversional cylindrical tubular lags. The self supported polyester spun-bonded media is used to make pleated element the spun-bonded media are started form 170 gsm to 270 gsm as per application demand, thickness started form 0.45 mm to 0.7 mm. TORAY Japan is the best quality producer of spun-bonded filter media in the world. Pleated elements are nomenclated in different name VIZ, Pleated Cartridge, Pleated Bag, etc. The elements are manufactured as per different pleat depth & nos. of pleat, different diameter, different fixing style, and different length. Form the application point, very less nos. Of OEM and supplier are successful to design efficient trouble free dust collector with is technologies. The key point to design pleated element consisting dust collector are

- Length of filter.

- Nos. of pleat.

- Pleat deep.

- Weight of fabric.

- Construction of element.

- Cleaning arrangement specialty.

- Center to centre between two elements.

- CAN velocity, INNER Tube velocity, Outlet of clean chamber velocity.

- Dust load selection.

- Inlet design of dust collector.

- High vacuum pulse valve selection etc.

We produce all most all the sizes of pleated element named pleated Bag & Cartridge. We have our special type Ruedo Pleated bag® with unique feature and fixing arrangement. Bottom loader, Top loader, Horizontal loading, Vacuum resistant inner support core and most flexible cutout hole diameter ranging from 156 mm to 168 mm. And our 3 lugs type Pleated Cartridge details are of Dia 130mm, 160mm, 225mm, 325mm. Length 500mm, 700mm, 1000mm, 1400mm, 2000mm. We also produce DIN Cartridge of Dia 325mm X660mm Long, FARR Cartridge: Dia 325 X1000 mm Long.

Pulse Valves

Pulse Valves Pleated Cartridge

Pleated Cartridge Filter Fabric

Filter Fabric Filter Bags

Filter Bags Din Type Cartridge

Din Type Cartridge Accessories

Accessories Dust Collector

Dust Collector Bag Cages

Bag Cages